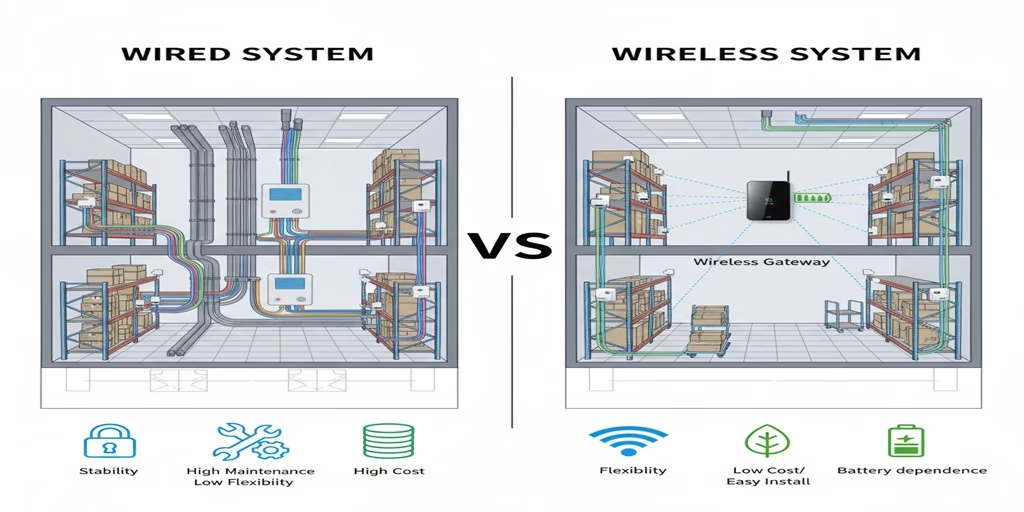

Wired vs. Wireless Temperature and Humidity Monitoring Systems:

What’s the Difference?

Wireless and Wired temperature and humidity monitoring systems represent two distinct deployment methods, each with its own advantages and disadvantages in terms of cost, deployment flexibility, stability, and applicable scenarios. Understanding these differences will help you make the best choice for your specific needs.

Comparison of advantages and disadvantages

Wired Temperature and Humidity Monitoring Systems

A wired system connects sensors to a data collector or control center via physical cables (e.g., RS485, RS232).

Pros:

- High Stability and Reliability: Wired connections are less susceptible to wireless signal interference, leading to more stable and reliable data transmission with virtually no data loss or delay. This is crucial for applications with extremely high data accuracy requirements, such as industrial control.

- Strong Anti-Interference Capability: Cables generally have better resistance to electromagnetic interference, especially in industrial environments.

- No Batteries Required: Sensors are typically powered directly through the cable, eliminating concerns about battery life and reducing maintenance costs.

Cons:

- High Deployment Cost: Cabling is complex and time-consuming, particularly in large or existing warehouses. It requires extensive engineering work like wall cutting, pipe laying, and cable installation, leading to higher labor and material costs.

- Poor Flexibility: Once the wiring is complete, it’s very difficult to move sensors. Adding or relocating monitoring points requires re-cabling.

- Not Suitable for Complex Environments: Wired systems are nearly impossible to implement in scenarios like historical buildings, high-altitude locations, or outdoors where running cables is difficult.

Wireless Temperature and Humidity Monitoring Systems

A wireless system transmits data using wireless technologies (e.g., Wi-Fi, Bluetooth, LoRaWAN, Zigbee), eliminating the need for physical cables.

Pros:

- Flexible Deployment and Low Cost: With no cumbersome wiring, sensors can be easily installed anywhere needed. This significantly reduces deployment time and lowers both labor and material costs.

- Easy to Expand: If you need to add new monitoring points, you just need to purchase new wireless sensors and add them to the system, which is very convenient.

- Suitable for Complex Environments: This is ideal for places where wiring is not feasible, such as museums, temporary storage facilities, cold chain transport vehicles, or building renovation projects.

- Highly Mobile: Some wireless sensors (e.g., those used for cold chain logistics) can move with the goods, enabling dynamic monitoring.

Cons:

- Limited Stability: Wireless signals can be affected by obstacles (walls, shelves) or electromagnetic interference, which may cause unstable signals, transmission delays, or data loss.

- Dependent on Battery Life: Most wireless sensors require batteries, which need to be checked and replaced periodically, adding to the maintenance workload.

- Network Security Risks: Wireless data transmission carries certain network security risks, requiring measures like encryption.

How to Choose?

The choice between a wired and wireless system depends on your application scenario, budget, and specific needs:

- Choose a wired system if you are building a new warehouse or industrial facility, have very high requirements for data real-time performance and stability (e.g., strict industrial control), and have a sufficient budget. A wired system is the more reliable choice in this case.

- Choose a wireless system if you are in an existing large warehouse, a food/pharmaceutical warehouse, or an environment where the layout needs to be frequently changed, or if you have a limited budget. A wireless system, with its flexibility, fast deployment, and low cost, is generally the better solution.

Currently, wireless temperature and humidity monitoring systems have become the mainstream choice for most commercial and logistics warehouses due to their high convenience and improving technical stability.