How to Choose the Right Temperature and Humidity Sensor:

An In-Depth Guide

Introduction

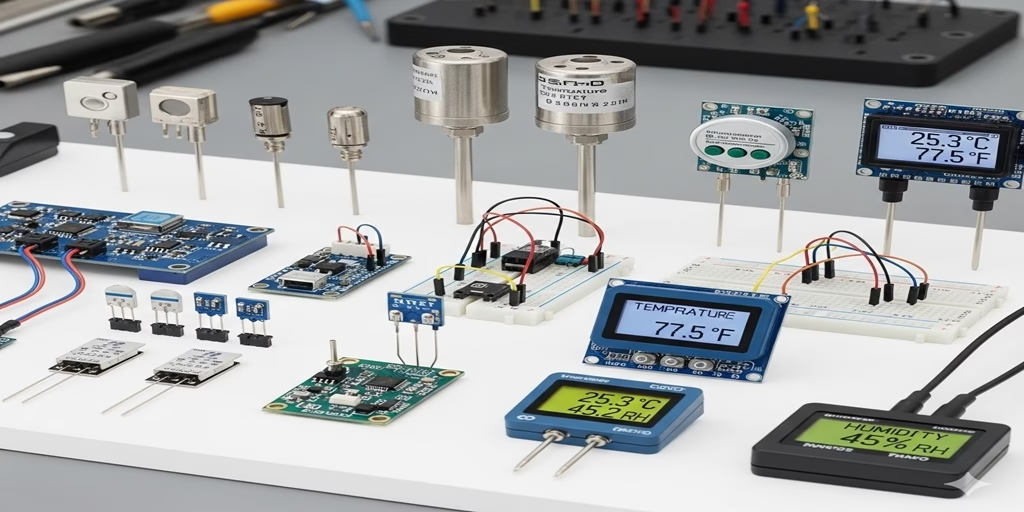

In today’s digital age, accurate environmental data is more crucial than ever. From adjusting comfort in smart homes and precise control in industrial automation to monitoring crop growth in agricultural IoT, temperature and humidity sensors are indispensable “sensory organs.” However, with an overwhelming variety of sensor models on the market—from inexpensive consumer products to costly industrial devices—making an informed choice has become a significant challenge.

This article aims to provide you with a detailed guide, delving into the key technical parameters, considerations, and comparisons of mainstream sensor models to help you find the optimal solution for your project.

Part 1: Understanding Core Technical Metrics

Before making a choice, you first need to understand the core technical metrics of temperature and humidity sensors, as they are the foundation for evaluating a sensor’s performance.

1. Accuracy

- Definition: The maximum deviation between the sensor’s measured value and the true value. This is one of the most important indicators for measuring sensor performance.

- Professional Analysis: Accuracy is typically expressed in percentages (%RH) and degrees Celsius (°C), for example, ±2% RH, ±0.5°C. For high-precision applications like medical or scientific research, an error as small as 0.1°C could affect the results, whereas for a household hygrometer, ±1°C accuracy is usually sufficient.

2. Resolution

- Definition: The smallest change a sensor can detect.

- Professional Analysis: Resolution determines whether you can capture minute environmental fluctuations. For instance, a sensor with a resolution of 0.1°C can detect a change from 25.0°C to 25.1°C, while one with a 1°C resolution cannot.

3. Measurement Range

- Definition: The upper and lower limits of temperature and humidity at which a sensor can operate effectively.

- Professional Analysis: When choosing a sensor, you must ensure its measurement range covers your application environment. For example, a sensor for indoor monitoring typically only needs to cover 0°C to 50°C, but a sensor for a cold storage or industrial environment requires a much wider range.

4. Response Time

- Definition: The time it takes for a sensor to respond to an environmental change and output stable data.

- Professional Analysis: Response time is critical for systems that require real-time monitoring or rapid reactions, such as fire alarms or quick ventilation systems. Response time is usually measured by t63 (the time to reach 63% of the final value) or t90.

5. Long-Term Stability

- Definition: A sensor’s ability to maintain its performance (such as accuracy) over long-term use.

- Professional Analysis: This is an easily overlooked but very crucial metric. Some low-cost sensors may experience drift after a period of use, leading to data distortion. For systems requiring long-term deployment (e.g., industrial automation, weather stations), choosing a sensor with good long-term stability can reduce maintenance and calibration costs.

Part 2: Decision Factors Based on Project Needs

After understanding the technical metrics, the next step is to match them to your specific project needs.

1. Application Scenario and Accuracy Requirements

- Consumer Applications (e.g., smart home, DIY projects): High accuracy is not a primary concern. DHT11 or DHT22 are good choices due to their high cost-performance ratio and ease of use.

- Industrial/Agricultural Applications (e.g., greenhouses, warehouse monitoring): Stability, accuracy, and durability are highly important. The SHT series or BME series are better choices.

- Professional/Research Applications (e.g., laboratories, weather stations): It’s essential to select the highest accuracy sensors, which often require professional-grade equipment with calibration certificates.

2. Interface Type: The Bridge for Communication

- Digital Interfaces: The preferred choice for modern sensors, as they don’t require external analog-to-digital conversion circuits, simplifying hardware design.

- One-wire: Simple, requiring only one data line, making it suitable for beginners (e.g., DHT11).

- I2C: The most common interface, needing only two lines (SDA, SCL), allowing for multiple devices to be connected, saving pin resources (e.g., SHT31, BME280).

- SPI: Faster, but requires more pins, suitable for applications needing high-speed data transfer.

- Analog Interfaces: An older technology that outputs a voltage signal and requires a microcontroller’s ADC for conversion. It’s prone to noise interference and is generally not used in most new projects.

3. Power Consumption and Size

- Power Consumption: A decisive factor for battery-powered wireless sensor nodes or wearable devices. Many sensors have extremely low power consumption in standby mode.

- Size: For space-constrained devices like micro-drones or embedded systems, choosing a smaller sensor is critical.

4. Ease of Use and Community Support

- Documentation and Libraries: Does the sensor have comprehensive data sheets and open-source libraries for popular microcontrollers (e.g., Arduino, Raspberry Pi)? This can significantly shorten the development cycle.

- Community Activity: A sensor with an active community (e.g., the DHT series) makes it easier to find solutions and reference code when you encounter problems.

Part 3: Comparison of Mainstream Sensor Models

Here, we will compare some of the most common temperature and humidity sensor models on the market to help you make an informed choice.

1. DHT Series: The King of Cost-Performance

- DHT11:

- Pros: Extremely low price, simple to use, widely available as a module.

- Cons: Low accuracy (±2°C, ±5% RH), low resolution, slow response, not suitable for precise measurements.

- DHT22 (AM2302):

- Pros: Moderately priced, accuracy is much higher than the DHT11 (±0.5°C, ±2% RH), and has a wider range.

- Cons: Response speed is still slow, requiring at least a 2-second sampling interval.

2. SHT Series: The High-Precision Benchmark

- SHT31:

- Pros: Extremely high accuracy, fast response, excellent long-term stability, I2C interface, and small package size.

- Cons: Higher price.

- SHTC3:

- Pros: A low-power version of the SHT series, with a compact size, making it suitable for wearable devices and IoT applications.

3. BME Series: The Multifunctional Integrator

- BME280:

- Pros: A “three-in-one” sensor that simultaneously measures temperature, humidity, and barometric pressure. High accuracy, selectable I2C/SPI interface, and low power consumption.

- Cons: Relatively high price. It is an unparalleled choice for projects that require pressure data.

Conclusion

Choosing a temperature and humidity sensor is not a simple task; it requires a comprehensive assessment of a project’s specific needs, budget, and technical requirements. There is no single “best” sensor, only the “most suitable” one for your particular project.

In summary, if your project is a simple beginner’s project or is cost-sensitive, the DHT22 is an excellent and cost-effective choice. If you are pursuing high accuracy and reliability and have a sufficient budget, then the SHT31 or BME280 will be your best choice.

Before making your final decision, be sure to thoroughly read the data sheet and use the guidance provided in this article to weigh all factors, ensuring your choice lays a solid foundation for your project’s success.

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Telegram (Opens in new window) Telegram

Related

Discover more from ChenAnIoT

Subscribe to get the latest posts sent to your email.